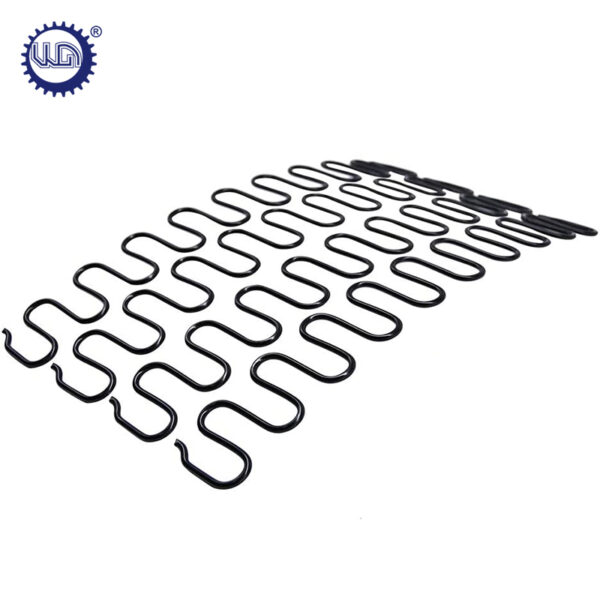

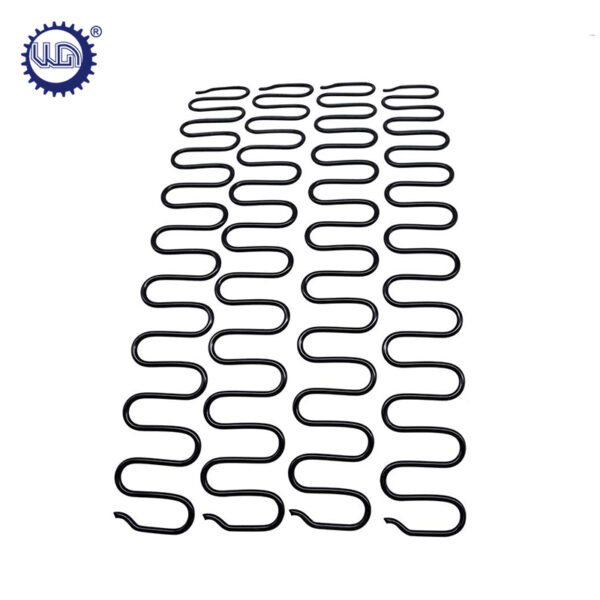

Customized manganese steel coil compression mold die spring

Mold springs are widely used in stamping molds, metal die-casting molds, plastic molds, and other elastic motion precision mechanical equipment, automobiles and other fields.

Description

Mold springs include: Japanese standard mold springs, European standard, German standard, American standard mold springs, and polyurethane springs. Usually mold springs refer to rectangular mold springs.

Feature

The mold spring is made of imported alloy steel material, which has the characteristics of high temperature resistance, fatigue resistance, and good toughness. The spring is resistant to high temperature to 280 degrees. Designed by professional engineers, it has a rectangular cross-section with rounded corners, which makes reasonable use of space. This process can reduce the stress concentration of the spring during high-speed extrusion and rebound. After more than three times of strong pressure treatment, the internal stress before use is eliminated, and the deformation, shortening, and fracture of the spring are avoided. The surface of the spring has been strengthened, which can make the surface structure strong, improve the strength of the stress concentration point, and extend the life of the spring.

Application

Mold springs are widely used in stamping molds, metal die-casting molds, plastic molds, and other elastic motion precision mechanical equipment, automobiles and other fields.