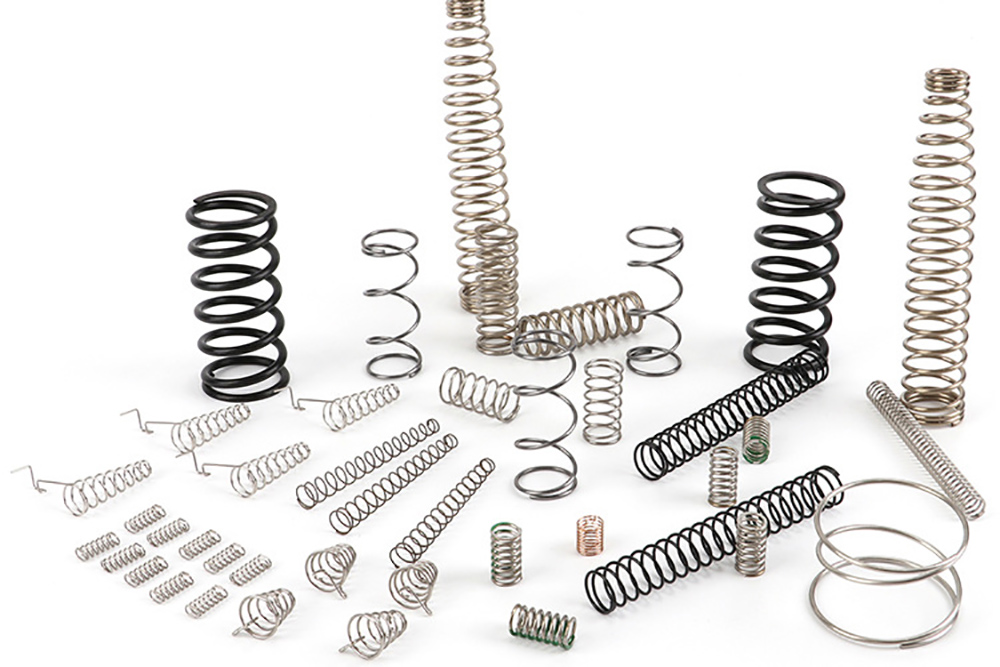

Custom stainless steel compression spring manufacturer

Compression springs are mostly circular in cross-section of materials used, and are also rolled with rectangular and multi-strand steel coils. Springs are generally of equal pitch and compression springs. There is a certain gap between the coils of the spring. When the spring is subjected to an external load, the spring shrinks and deforms to store deformation energy.

Description

Compression springs (compression springs) are helical springs under pressure. Most of the materials used are circular in cross-section, and they are also rolled in rectangular and multi-strand steel coils. The springs are generally of equal pitch. The shapes of the compression springs are: Cylindrical, conical, convex and concave shapes, and a small amount of non-circular shapes, etc., there is a certain gap between the coils of the compression spring, and the spring shrinks and deforms when subjected to an external load to store deformation energy.

Feature

The compression spring provides resistance to the external load pressure. Compression springs are generally coiled metal wires with equal pitches and fixed wire diameters. Compression springs use multiple open coils to provide resistance to external load (such as gravity pressing down on a wheel, or body pressing on a mattress). That is, they push back to resist external pressure. Compression springs are generally coiled metal wires with equal pitches and fixed wire diameters. In addition, there are also conical compression springs, or a combination of conical and linear springs. According to different application areas, compression springs can be used to resist pressure and/or store energy. Round metal wire is the most commonly used compression spring, but there are also compression springs made of square, rectangular and special-shaped metal wires.

Application

Compression spring wire springs are used in everything from home appliances to motorized equipment, motors, etc., because it is the required type of spring. By the load acting on them or their ends are compressed, the compression spring is compressed by the design of the wire trying to return the spring to its original shape, so that the load is pushed back. Main application directions: medical breathing equipment, medical mobile equipment, hand tools, home care equipment, shock absorption, engine valve springs.